High Temperature Graphitising Furnace Commonly used in 3000 ℃ within the Ultra-High Temperature Furnace, used for a variety of high thermal conductivity graphite film (PI film), lithium battery anode materials, carbon materials, carbon and graphite production of carbon materials carbon, graphite; application of carbon fibre filament sizing graphite and other materials can be sintered in the carbon environment, the use of medium-frequency induction heating, graphite furnace power is lower, to provide a complete graphite furnace furnace loading diagrams, should be the customer's special requirements Hydraulic pressurisation of graphitising furnace can be provided

- 3000 ℃, commonly used temperature 2900 ℃.

-? the working atmosphere: vacuum replacement Ar2, N2 protection (micro-positive pressure)

-? temperature measurement: far-infrared optical temperature measurement temperature range 1000 ~ 3000 ℃ or 0 ~ 3000 ℃; temperature accuracy: 0.2 ~ 0.75%.

-?Temperature control: programme control and manual control; temperature control accuracy: ±1℃.

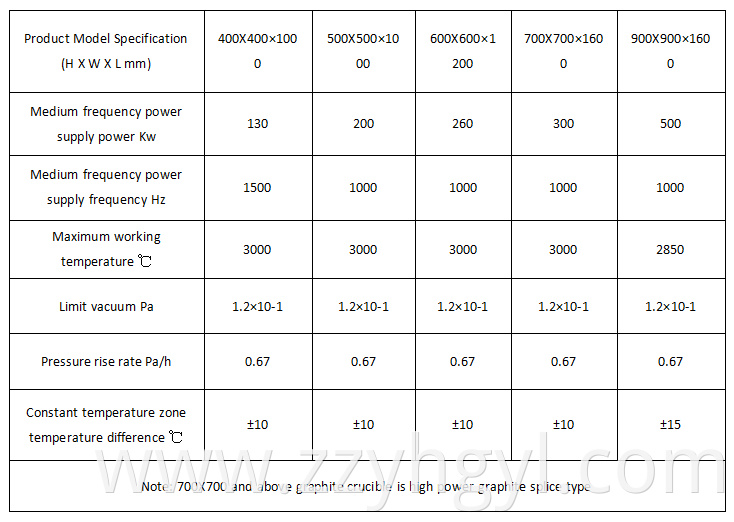

-?Equipment adopts medium frequency power supply induction heating, high efficiency, low power graphitising furnace: unique furnace chamber design, greatly improving the furnace temperature uniformity. Limit heating speed: 200 ℃ / min (empty furnace, depending on the volume of the high-temperature zone and the structure of the furnace chamber) furnace temperature uniformity ± 10 ℃, temperature control accuracy ± 1 ℃.

-?low energy consumption: thickened alumina insulation material, heat insulation and refractory effect, heat loss is small, heating speed.

-?Long service life of wearing parts: the bottom of crucible is padded with high-strength hard composite felt to ensure that the graphite crucible is flat and uniformly stressed at high temperature, which is 1.2 times of the service life of similar products.

-?Provide complete graphitising furnace loading diagram.

-?According to the special requirements of customers can provide graphitising furnace hydraulic pressurisation